Not known Facts About What is the difference between a lock washer and a vibration

An Unbiased View of How Effective Is Disc Spring Washer? - Nord-Lock Group

I hope I explained this well, which it includes to the discussion, rather than muddying the waters. Last edited by Weapon Doc on Thu Oct 26, 2006 9:11 pm, edited 1 time in total.

You have no products in your shopping cart.

In order to offer total functionality, this website requires your explicit grant keep web browser cookies. If you don't enable cookies, you may not have the ability to use particular features of the web website consisting of but not limited to: log in, purchase products, see personalized material, switch between website cultures.

The 30-Second Trick For Wave Spring Washers (SPEC®) - Associated Spring Raymond

I hereby accept that the offered information can be used for marketing purposes and targeted site material. You can find more information on our personal privacy page.

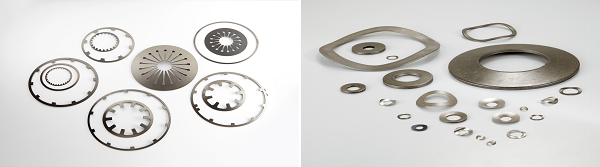

Spring washers are locking washers that are utilized when there is a requirement to avoid a fastener from loosening as a result of vibration. They are also typically called split lock or split ring washers. A spring washer has a split in the washer area that when tightened each side of the split bites into the nut and the installing surface.

There are two kinds of spring washer, square and rectangle-shaped section. This refers to the shape of the split end area. A simple way to inform the distinction is that when seen from above, rectangular area spring washers look flatter than the square area variants, which look a lot more rounded.

3 Easy Facts About Spring Washers Manufacturer - Plated and Metric Spring Explained

As the washer is tightened under load, the vertical cut ends of the washer grab the nut and bind against it. When the nut is completely tightened, the split in the washer need to still be slightly out of alignment. This is visual proof that the spring washer is still operating as intended and in fact putting in a force on the fastener, as displayed in the image listed below; If the nut is overtightened the impact of the spring washer is dramatically decreased, as the split ends of the washer are then brought into positioning as the washer is flattened, decreasing or totally getting rid of any stress on the fastener.

If an extra washer is needed to spread the load (as in our image above) it ought to be used in between the spring washer and the mounting surface, i. e. the spring washer should be placed beside the nut. Are there Key Reference to spring washers? This quite depends on the application.